Since 2015: A Fusion of Academic Rigor and Master Craftsmanship

Our story began in 2015 under the name Picolo Velo, rooted in a uniquely Canadian collaboration between engineering precision and the timeless skill of master woodworking. From the outset, our mission was clear: to craft a high-performance bicycle that merges academic insight with artisanal mastery.

Now known as Sila Cycles, we remain guided by the same principle. Inspired by the Inuit concept of universal connection (“Sila” or “Silap Inua”), we believe a great bike must harmonize nature, science, and craft.

Engineered to Perform

Each Sila bike is born in our Montreal, Canada workshop and designed with intent. Our frames are made from solid ash wood—not for tradition’s sake, but for performance. We chose ash after extensive analysis of its mechanical properties: its vibration-damping flex, its strength-to-weight ratio, and its dynamic responsiveness under load. These aren’t abstract ideas—they’re properties we’ve tested, measured, and optimized.

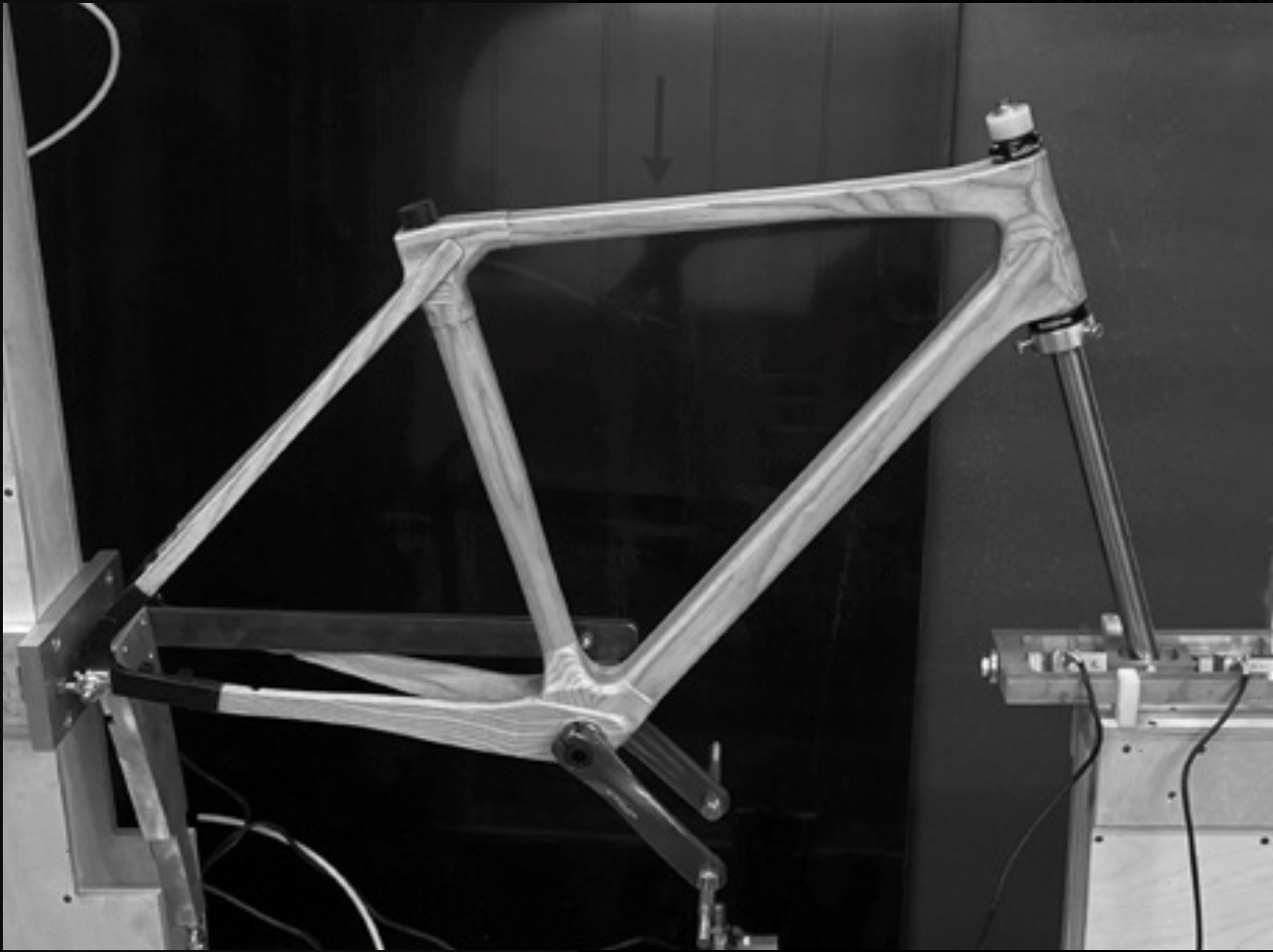

Using a mix of finite element simulations and lab-based mechanical testing, we tune each frame’s layup for lateral stiffness, vertical compliance, and fatigue resistance. The result: bikes that climb efficiently, absorb rough terrain, and feel alive beneath you.

Crafted to Last

Where engineering ends, craft begins. Our frames are hand-built using advanced lamination, steam-bending, and woodworking techniques typically found in custom furniture or instrument making. This isn’t outsourced or automated—it’s done in-house, by Canadian master woodworkers who understand how wood breathes, flexes, and ages.

The geometry is gravel-ready and performance-oriented: long enough for stability, responsive enough for spirited riding. You can spec your build with electronic SRAM drivetrains, carbon cockpits, and premium gravel wheels. Each component complements the frame's unique ride feel—smooth, silent, and unmistakably natural.

Ride Sila

A Sila bike is more than a machine. It’s the physical result of years of research, experimentation, and refinement—a rare blend of technical rigor and soulful craftsmanship. Proudly Canadian, it’s built for those who want to feel the trail, the road, and the story behind every ride.

A force of nature

We craft high-performance wooden bikes that blend design, durability, and exclusivity. Made from ash wood, our frames harness nature’s unmatched ingenuity. Sila offers a reliable, comfortable, and eco-conscious ride—built for those who seek connection with the environment and their bike.

Inspired by the Inuit concept of universal connection (“Sila” or “Silap Inua”), we design each bike to unite nature, machine, and rider.

Ready to ride a marvel of strength, agility, and elegance? Join us.

Your comfort zone

Everything at Sila leads to comfort. From the raw material of our frames, to the choice of components, to the meticulous care given to every detail of the assembly. Everything! Ash alone gives our frames a 21% higher absorption capacity than carbon. Thanks to its many qualities, its ideal weight, and our love of cycling, we can proudly turn this immense potential into a promise to take you further, with greater ease and comfort. It's no wonder that wood is now a favourite among seasoned cyclists.

Science and Innovation

-

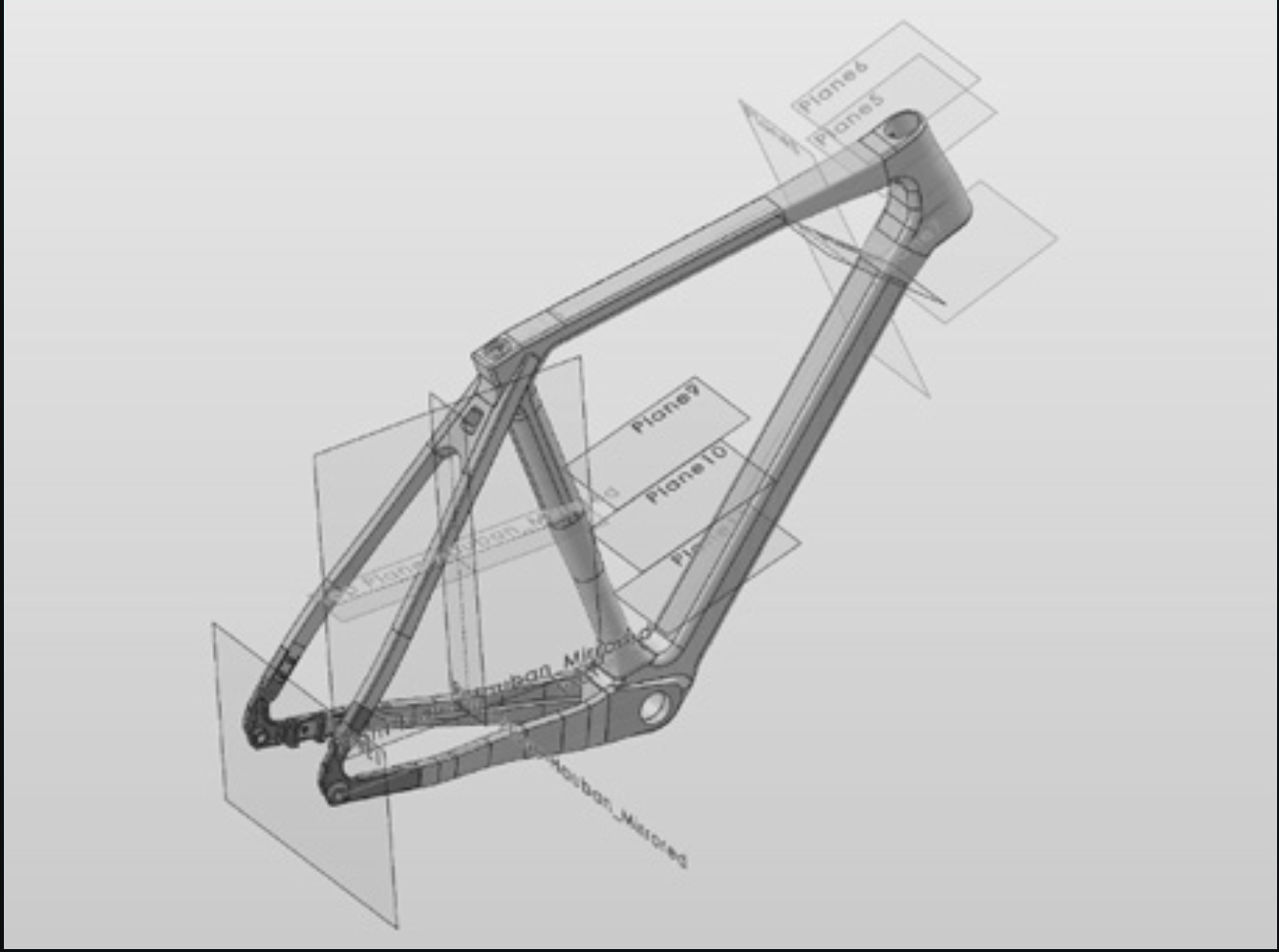

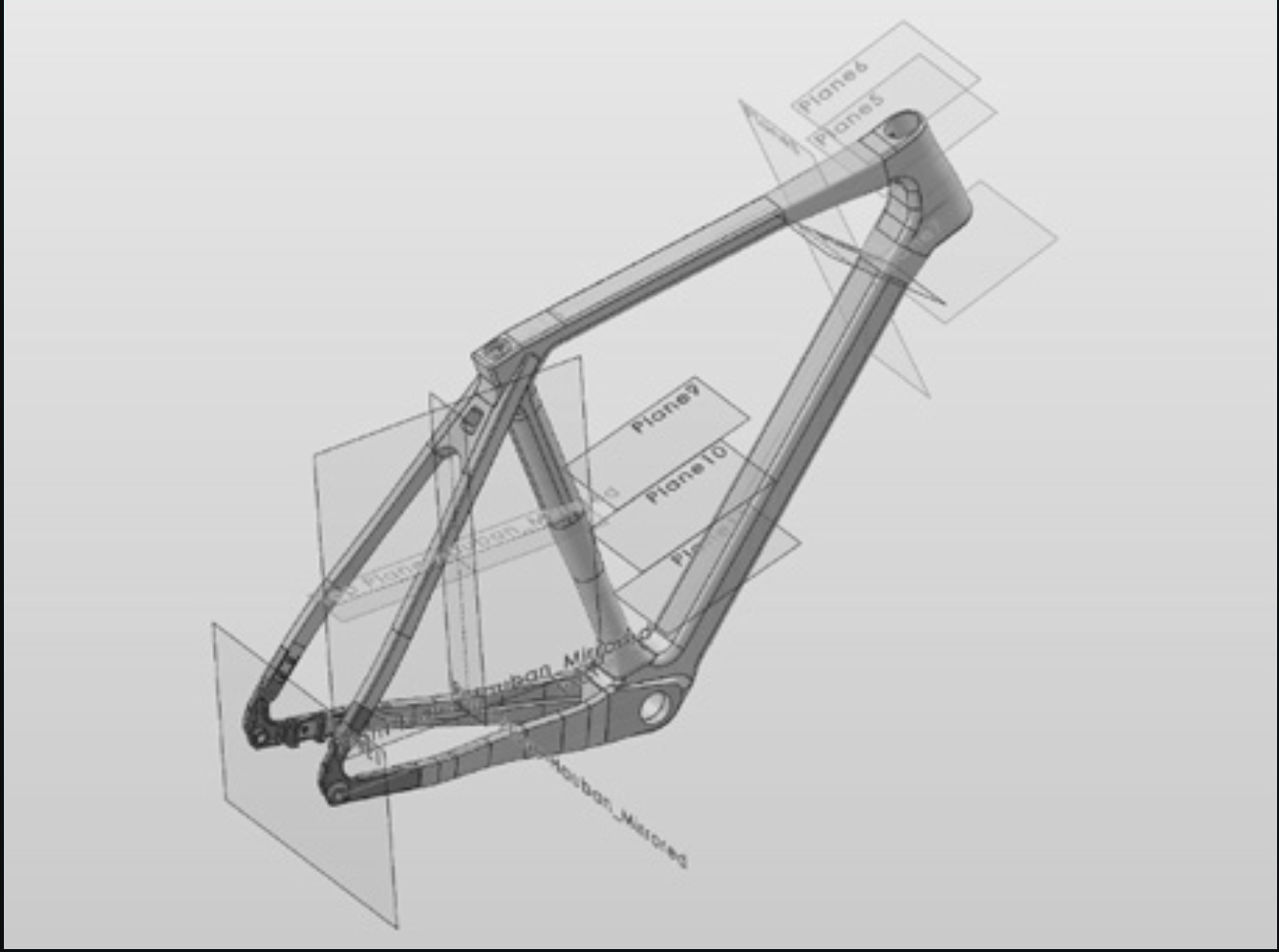

Cutting-edge software

Sila uses cutting-edge technology for the design and manufacturing of its frames. We use SolidWorks to create our models. We then take advantage of the flawless precision of advanced robotics to cut the wooden components.

-

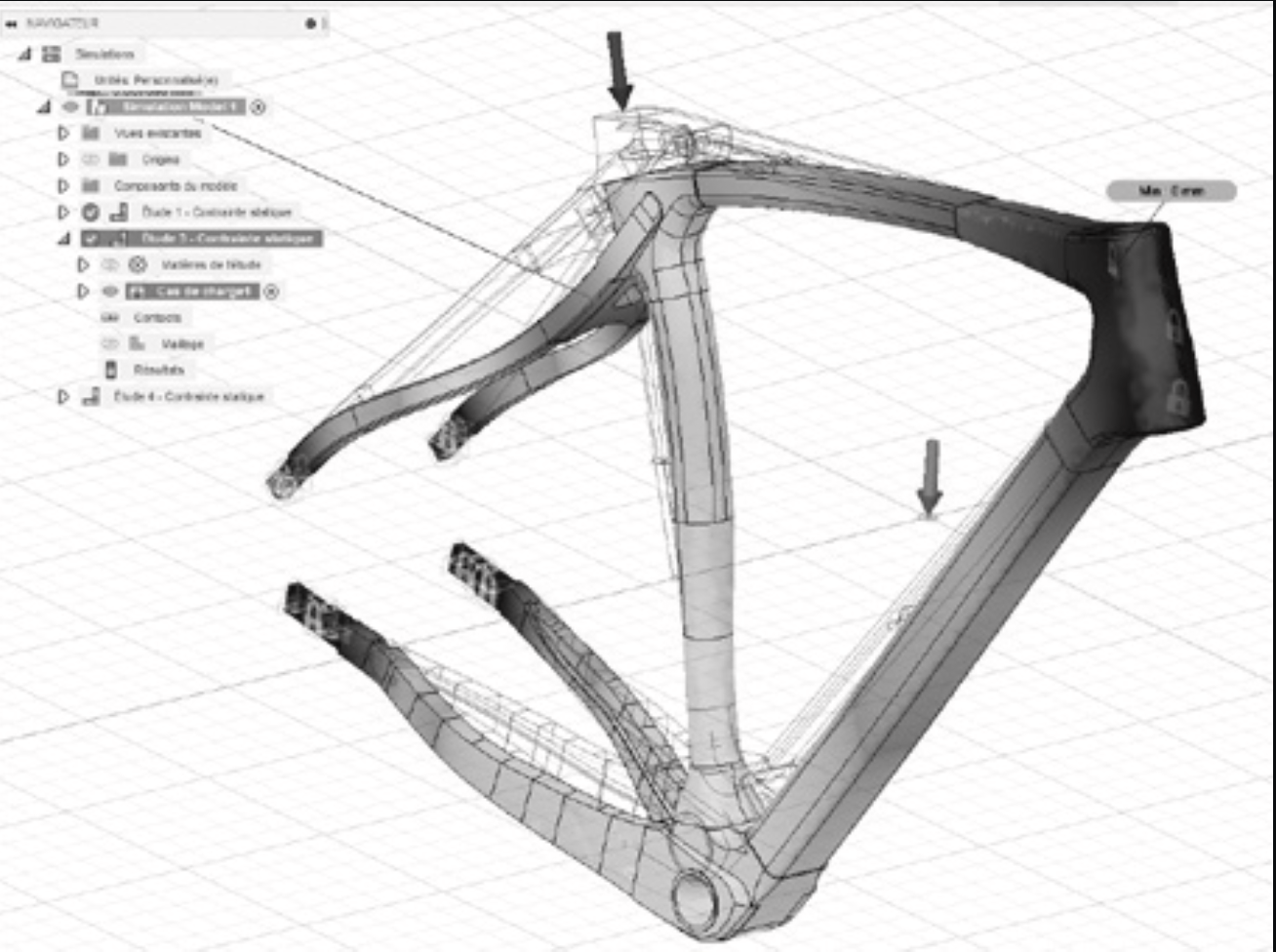

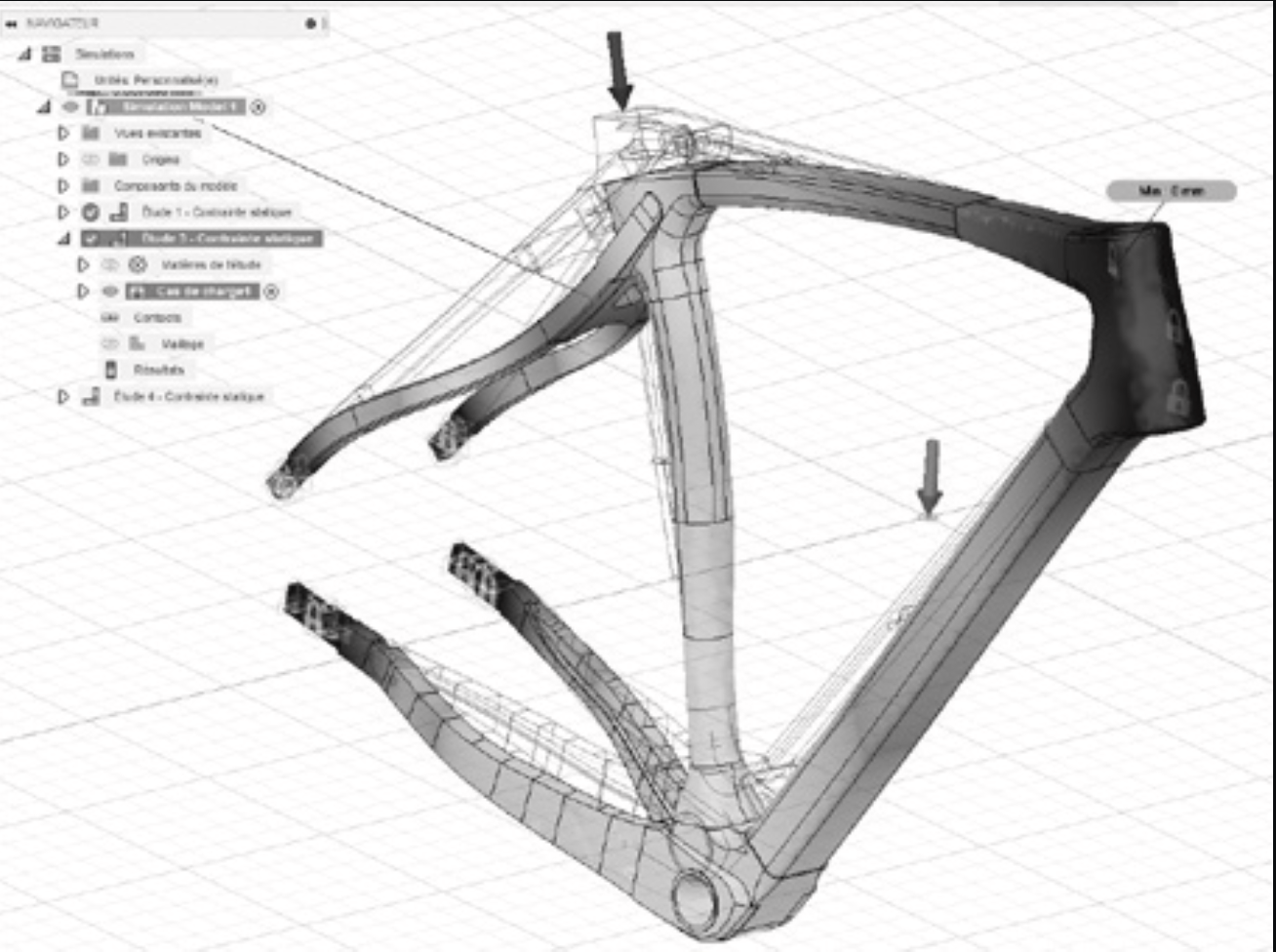

Finite Element Simulation and Analysis

To optimize the design of our frames and components, Sila Cycles relies on proven engineering tools and methods. In addition to mechanical testing conducted in the lab, numerical simulations are used to analyze the behavior of our bikes with a view to continuous improvement.

-

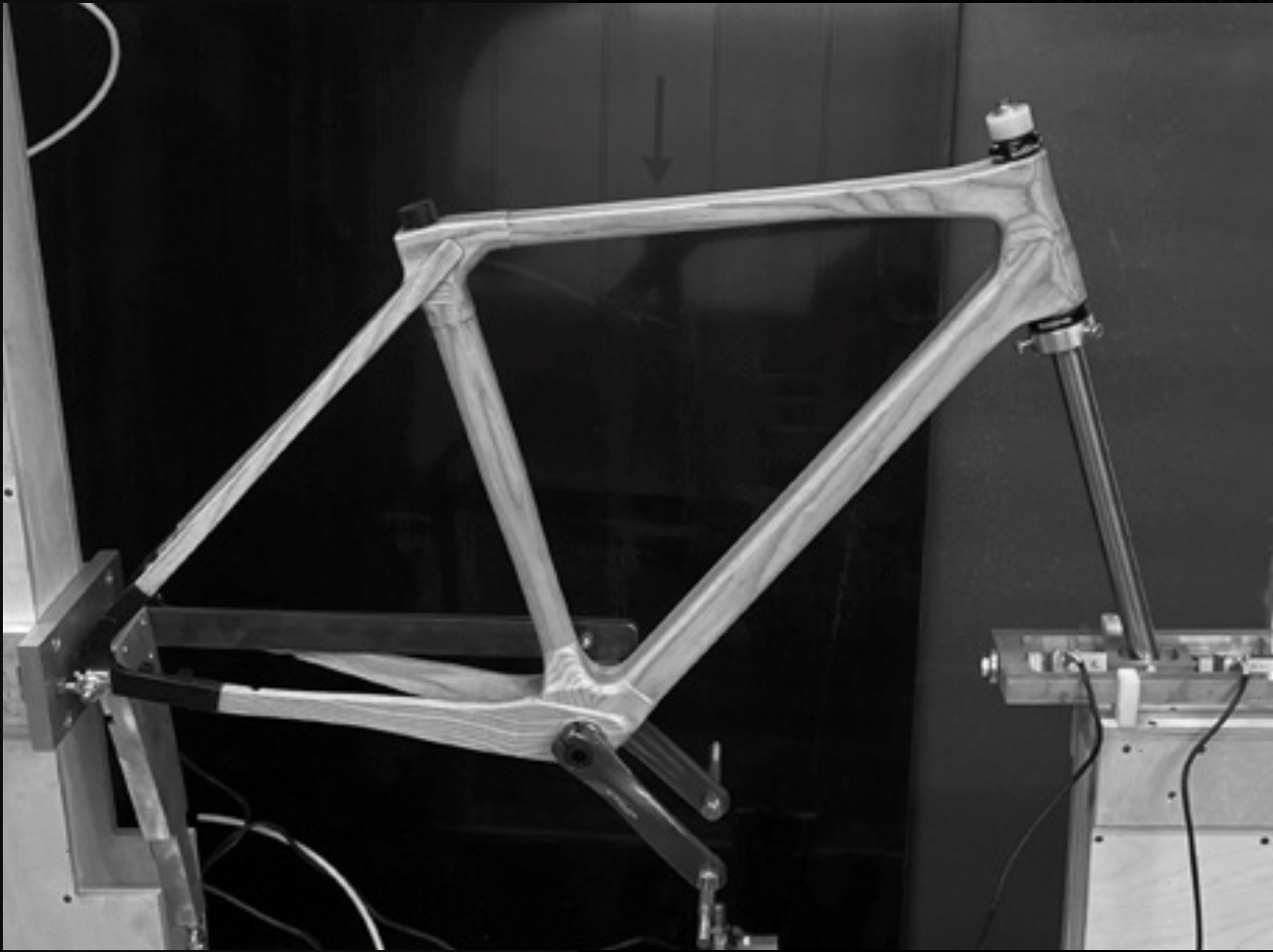

Meeting the Highest Standards

Sila validates the mechanical strength of its frames by testing them according to the most demanding protocols, including the ISO 4210-6 standard. Multiple impact tests in various directions—on both the fork and the frame—have been successfully completed. These include fatigue tests reaching up to 100,000 load cycles.